Industrial Suppression

Fire Alarm Installation, Inspection, Testing & Maintenance

Areas We Serve

-

Cherry Point, North Carolina

-

Concord, North Carolina

-

Cool Springs, North Carolina

-

Emporia, Virginia

-

Emerald Isle, North Carolina

-

Fort Mill, South Carolina

-

Henrico, North Carolina

-

Kannapolis, North Carolina

-

Lewiston Woodville, North Carolina

-

Mint Hill, North Carolina

-

Newport, North Carolina

-

North Myrtle Beach, South Carolina

-

Pawleys Island, South Carolina

-

Rock Hill, South Carolina

-

Salter Path, North Carolina

-

Spring Lake, North Carolina

-

Williamston, North Carolina

Additional Services

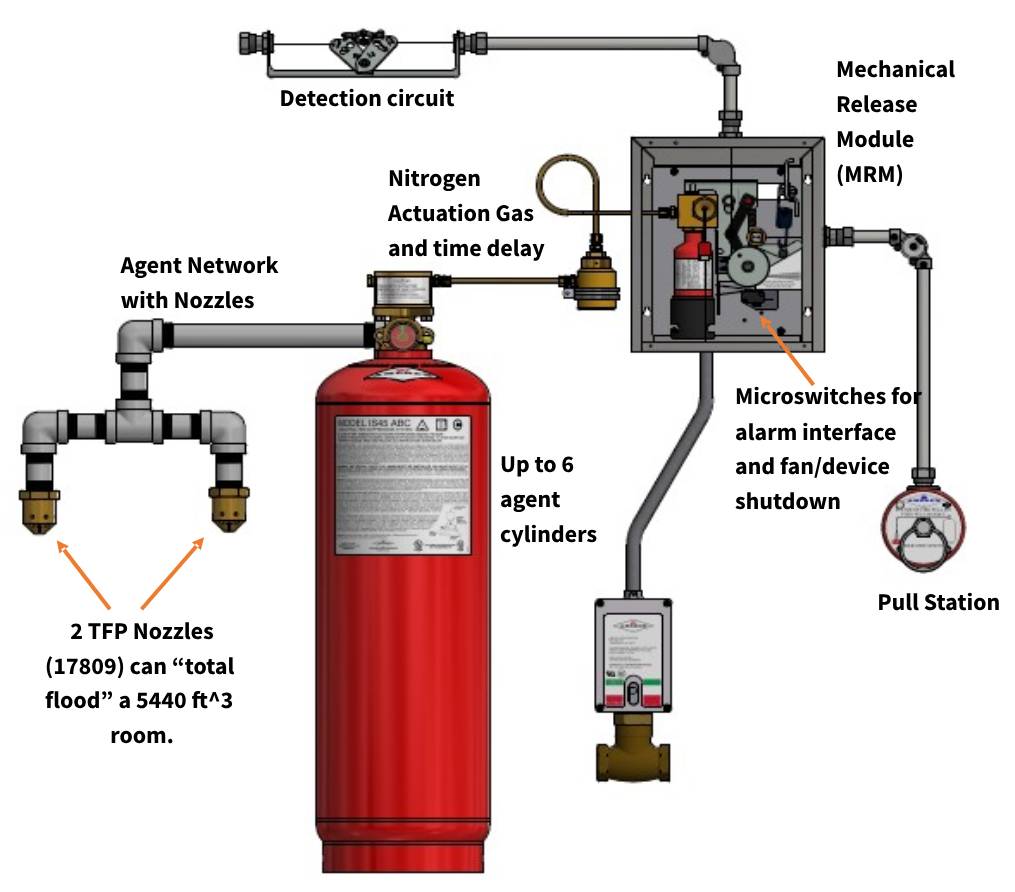

Pressure Release Module Advantages

PRM (P/N 16795)

Amerex Industrial Systems with the Pressure Release Module (PRM) is one of three listed ways of industrial fire detection and suppression from Amerex. The primary method of operation is a manual pull station(s) located in the path of egress. The automatic detection method utilizes a proven linear pneumatic detection tube that easily routes through the hazard area. Both manual and automatic options trigger the actuation networks; mechanical gas valves, and offers electrical micro switches for shutdown functions. A low pressure switch is provided for supervisory connections to a fire alarm control panel and/or the optional low pressure indicator. The panel is supplied with the PRM End of Line Fitting and two sealing balls to complete the detection line. When the pressurized tube is broken by excessive heat, the accumulator releases pressure and the system actuates. Easy routing in and between hazards makes the PRM tubing extremely useful when protecting industrial hazards.

PRM Advantages for IS settings

- Up to 300 ft of continuous detection

- 16’ ceiling heights with no spacing reduction

- 3 year change interval (no climbing to the ceiling every 6 months)

- Intrinsically Safe

- Ability to run through pits and on ceilings

- Panel fits a 15in^3 nitrogen cartridge which can release 10 IS cylinders

- Provides end to end detection on the entire run of tubing.

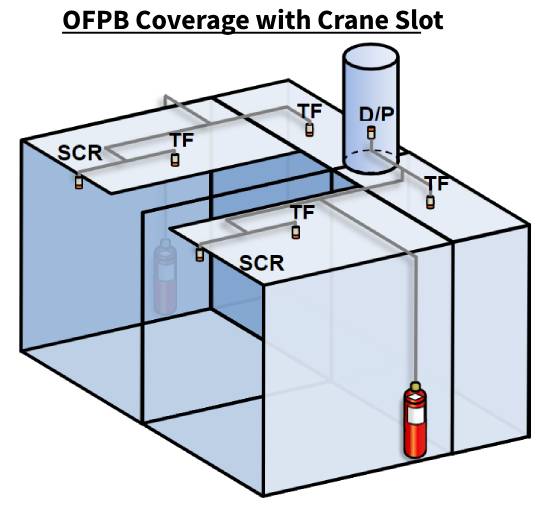

Open Front Paint Booth and Crane Slot Coverage

Better Protection for Unique Hazards

Amerex’s OFPB coverage offers the highest allowable open front heights of any pre-engineered system on the market. While other systems max out at 12 feet Amerex systems can protect an OFPB up to 18’ 6” high. For booths with a Crane Slot in the ceiling, Amerex posted a recommendation letter in 2014 for this unique hazard. Listing agencies do not address crane slots but Amerex has conducted rigorous in house fire testing to ensure we could protect this unique hazard with confidence and with proper coverage. Amerex testing revealed that our standard UL listed OFPB coverage was sufficient to protect both the OFPB and the crane slot without alteration.

Crane and OFPB Advantages

- OFPB coverage is best height in the industry.

- Crane Slots are uniquely tested at Amerex for this non-listed hazard

- Maximum dimensions are matched with OFPB hazard coverage.

- Very useful in spray applications where a part stops inside the hazard.

- Under certain configurations, crane slot coverage can allow for the integration with automated lines.

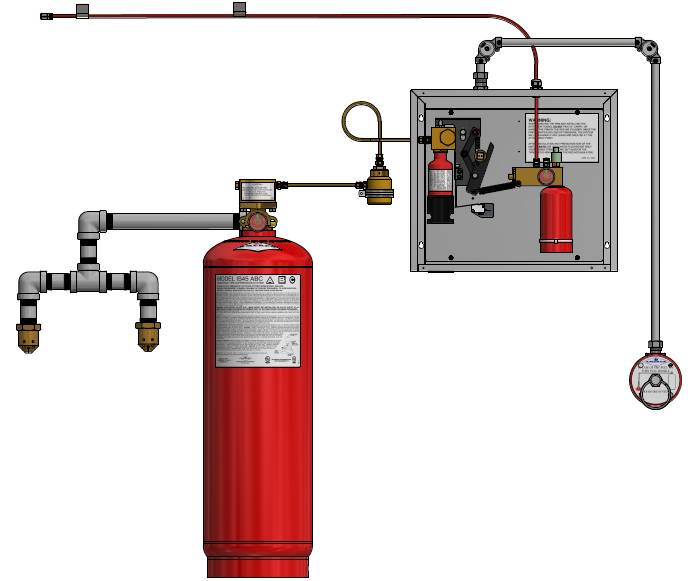

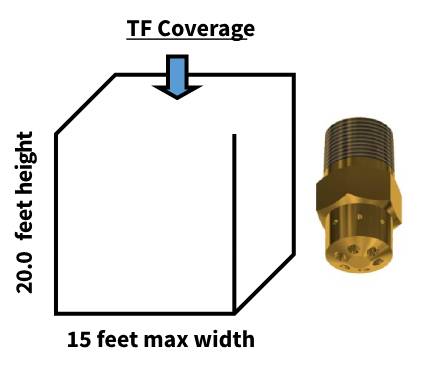

Total Flood Hazard Coverage

Amerex offers the most efficient Total Flood Coverage

Amerex Total Flood Coverage can cover many unique applications in enclosed areas (with up to 5% open wall area) very efficiently. It can utilize a mix of standard (overhead) or perimeter (wall based) coverage. If more than 5% of the area is open then Local Overhead application should be used. Some examples of these type of hazards are as follows:

- Approved alternative to overhead sprinklers

- Any room or area that stores Class B materials.

- Mobile Hazard storage (freezers, connex’s, etc)

- Paint Mixing Rooms

- Pump or Generator Rooms where configurations allow.

Amerex Total Flood Advantages

- Using of mix of industry leading TF and TFP nozzles allowed

- Each TF nozzles coverages up to 20’ high, 15’ max side (1440 cu ft)

- Each TFP nozzle covers 12.5’ high by 16’ wide (2720 cu ft)

- UL tested coverages

- Industrial strength brackets allowing for high FE mounts along with Large coverage modules greatly reduce piping install time.

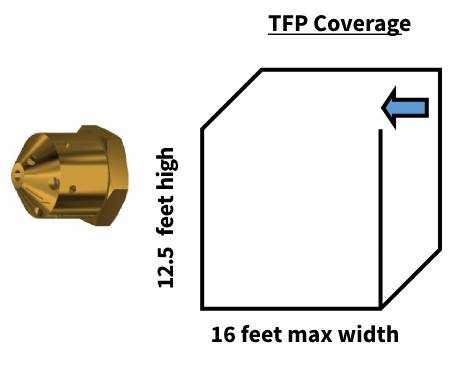

Amerex Total Flood Perimeter Coverage

TFP Nozzle (P/N 17809)

The Amerex TFP nozzle is the newest and most advanced Industrial System nozzle on the market that allows you to do more with less. It has the ability to flood up to 5440 cu ft with just 2 nozzles and a single IS45 agent cylinder. This makes the install time much quicker due to less pipe, fittings, and seals for distributors.

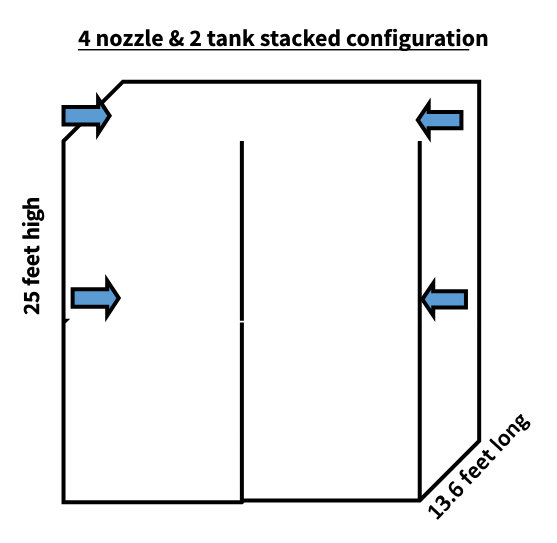

TFP nozzle Advantages

- Best in industry coverage of 2720 cu ft per nozzle.

- 12.5’ module height by 16’ side length (max 2720 cu ft)

- A 25’ high by 16’ wide can be created by stacking modules.

- TFP nozzles can be pointed towards each other from opposite walls of a room allowing for coverage of rooms up to 32’ wide.

- No penetrations through the ceiling, everything can be completed through the side walls.

Amerex Curtained Work Station

Recommended Coverages

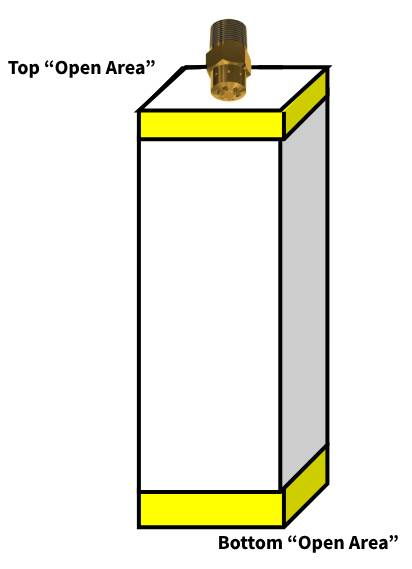

Amerex and FEMA continue to stress the importance of protecting curtained limited finishing workstations as required in NFPA 33. During Testing proper suppression was achieved by doubling the listed Amerex Vehicle Paint Spray Booth coverage. This allowed for proper compensation for the up to 8.3% total open area on the exterior of the booth. As with our standard coverage as height increases, maximum L x W decreases to meet the volume limitations.

Curtained Station Key Points

- Amerex is the only Manufacturer who formally stands behind a solution to Curtained Limited Finishing Work Stations.

- As height increases the percentage of open area decreases (fixed gaps at top and bottom) allowing protection for up to maximum VPSB coverage height.

- A simple doubling of the agent provides conservative coverage based on testing.

- See the FEMA white paper for more info on testing: